Olive production and bottling process of this unique product known as “Olio Zo”.

Mr Antoniou, owner of the olive grove where Olio Zo is produced and bottled, presents and explains the entire process followed to deliver this excellent product to you.

From the olive tree blooming stage to the olive harvest, a professional agriculturist is responsible for the correct and safe growing of the olives, through systematic monitoring. It is important that the olives that will produce our olive oil are healthy, if we wish to obtain a top-quality olive oil. To achieve this, we follow a protocol; we place yellow adhesive traps on each olive tree to monitor the number of various enemies of our olives, and whenever we identify a harmful number of insects, we intervene with the use of appropriate and approved organic products, since this is a biological-organic olive grove and the use of chemical products is not allowed under any circumstances.

Around the end of August, LACON, a German company offering organic product certifications, visits our olive grove to check whether we follow protocol. Also, experienced LACON staff calculates the quantity of olives we will have in the current year. All this is recorded in the organic farmer’s logbook, which every organic farmer is obliged to keep. About two months before the fruit’s full ripeness, ie. while the fruit is still green, we start the harvest. In this way, we obtain the olive’s juice (extra virgin oil) which is green, rich in aromas, vitamins, antioxidants and phenols, and is characterised by a fruity and spicy taste.

To produce a litre of organic extra virgin oil, we need approximately eleven kilos of olives, as opposed to common olive oil which uses four kilos of olives per litre of oil. This is why it is not widely available and costs three times more – which is why it is called the “elite olive oil”.

The harvest stage is equally important to obtain a top-quality olive oil. This is where the second protocol is followed. The olive harvest from the trees is done using special machinery, ie. shaker machines with an umbrella. This keeps the fruit intact, protecting it from being damaged or falling to the ground, since it ends up in the umbrella. Due to the very high cost of this machine, most producers use various types of olive harvesters, combs and nets, which damages the fruit and gives poor quality olive oil. Once the olives are harvested using the shaker machine, they are placed in dedicated, small plastic boxes for ventilation and to avoid overheating. On the same day, the olives are transported to an organically certified olive mill. This is when the third protocol is implemented – a very important protocol to achieve our goal. The organic olive mill’s competent person receives the olives, weighs them and records the exact quantity of each organic farmer to a dedicated register, and, finally, issues a certificate which includes the accurate total olive quantities received and the accurate olive oil quantities produced. We are obliged to present this certificate to LACON, the organic product certification company. In this way, the true quantity produced by each organic farmer is certified.

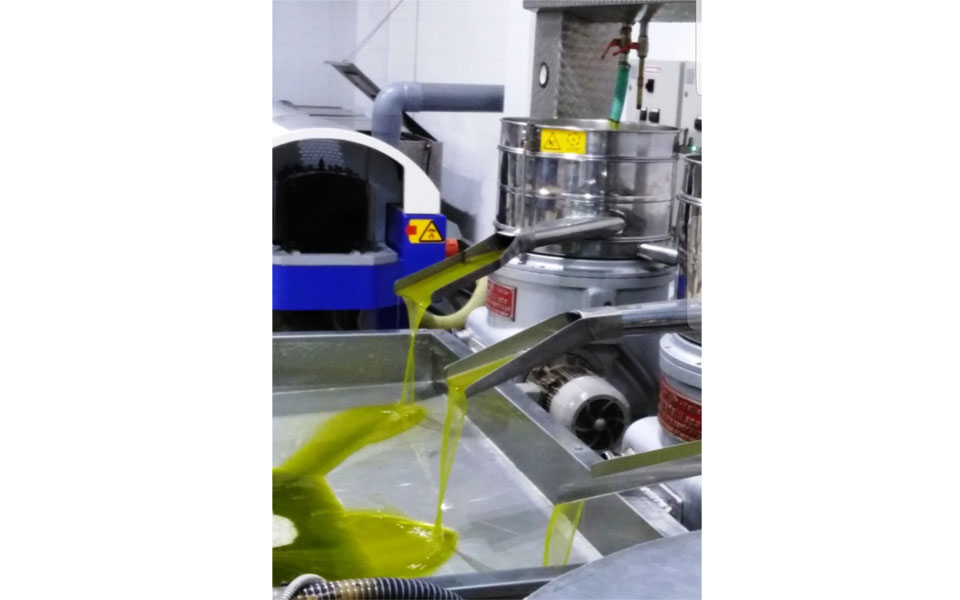

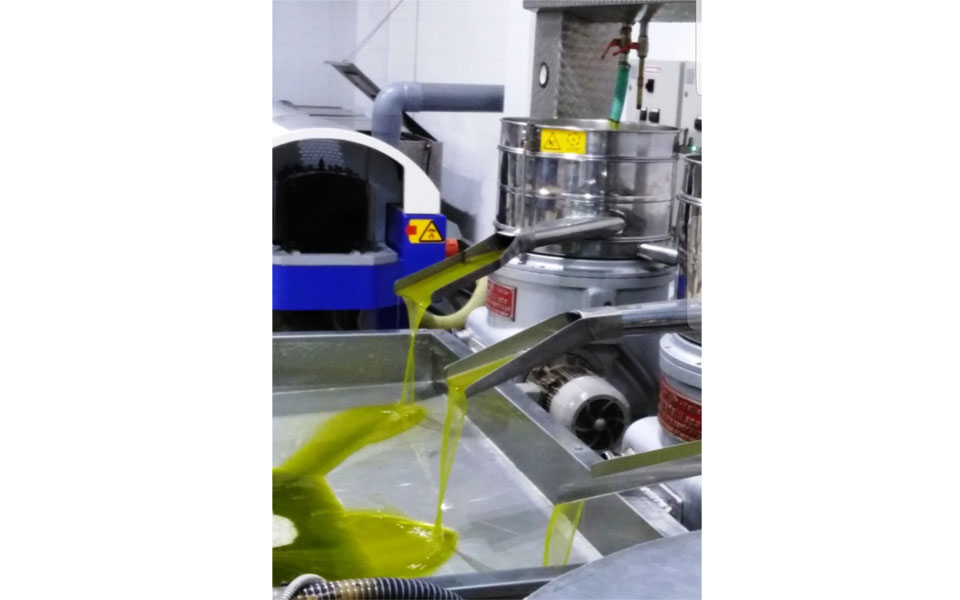

Then, the olive mill’s competent person puts the olives in a dedicated box, which is then transferred by an automatic belt to be washed with clean potable water. After being washed, the olives are automatically transferred to the crusher to end up in dedicated tanks for the paste malaxation. The paste can remain in these tanks for thirty minutes only. This is very important because, if it stays longer in the tank, our olive oil is oxidised and loses its aromatic and nutritious properties. The temperature in the tanks must not exceed 27°C. This process is called “Cold Extraction”.

We receive the olive oil in small, clean stainless-steel containers. At this stage, the fourth protocol is implemented, which is equally important. We transfer our olive oil to our storage space, which must comply with all requirements governing the correct and safe storing of our olive oil. We put the olive oil in big, clean, stainless-steel tanks of a 1000 litre capacity each, and we seal them so that the olive oil does not come into contact with oxygen or light. Our storage space is equipped with air conditioning to maintain the temperature stable at 15°C. After following all the above-mentioned protocols, our olive oil can maintain the same quality, without deteriorating, for much longer than 18 months, which is the period the studies conducted up to date support it can last for.

Finally, we move to the bottling stage, which is carried out in our own organic bottling hall, which is controlled and certified with a certification of compliance of the safety system in food production (HACCP). For the bottling process, we use a specifically designed stainless-steel tank of 200 litres which is fitted with a stainless-steel pourer to help us fill the bottles. We use the small stainless-steel containers to supply this tank. Under no circumstances do we use electric pumps to transfer our olive oil from one tank to the other, nor to fill our bottles. The use of such pumps only saves time to the detriment of the olive oil quality. This is because, during the olive oil transfer through the pump, its flaps move, allowing the penetration of oxygen, which increases its temperature, causes oxidation and releases various other metals and compounds; this downgrades the olive oil’s quality and purity.

Our bottling hall is only used for our own organic products and all these processes are carried out by us.

These processes are carried out strictly based on our controlled protocols, and this is why our company’s policy is to sell products which are exclusively produced and originate from our olive grove.

Its limited edition and “gourmet” characterisation justifiably make it unique and special, since, from the very beginning and up until it reaches our hands and, finally, our organisation, we have shown respect and bowed to nature, but also to the human being whose love and enthusiasm led him to strive and finalise, in the most natural way possible, this blessed and excellent product, a product of our land.